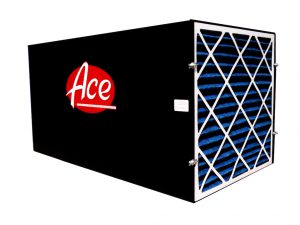

Ace Industrial Products, headquartered in Saint Louis, Missouri, has designed and manufactured welding fume extractors and related equipment for over 50 years.

We take pride in providing high quality, American-built products that are simple to use, affordable to own, and most of all, highly effective in protecting welder health and safety.

Latest News

For regular visitors to the Ace website who rely on this site as a product information resource, you have probably noticed a few changes. We’ve updated and refreshed the site, cleaning up the pages and making the interfaces more functional, while keeping all essential information still in place. In fact, our popular Documentation sections on […]

The AWS has made available a very useful resource for all welders and metalworkers entitled Safety in Welding, Cutting and Allied Processes. This guide is the official ANSI standard Z49.1 1:2012. This standard covers all aspects of safety and health in the welding environment, emphasizing oxygen gas and arc welding processes with some coverage given […]

For 51 years, Ace fume extractors have been manufactured at our plant in St. Louis, MO. Each of our extractors is built by hand by skilled assembly technicians who know our products better than anyone in the world. For these reasons, we take pride in the quality our products, of our service, and of our […]